Stretch

Hey! There’s no easy button for a body like this!

It took me ten years to catch the ol' Plymouth so here's to hopping it doesn't take that long to build it.

My Garage is quite full of the Oakland project. I hope to have the wood done on that by Christmas. Once that's out of there I'll get the little Plymouth in and torn down. I plan to build a rotisserie right after its stripped down.

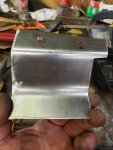

As for today, I sand blasted and painted the clutch, brake, & throttle pedal assembly. I need to start somewhere and I have these parts just hanging around so, Pitter Patter I guess.

Here's a few pictures of the car the day Jass and I picked it up and then some pictures of the pedals.

My Garage is quite full of the Oakland project. I hope to have the wood done on that by Christmas. Once that's out of there I'll get the little Plymouth in and torn down. I plan to build a rotisserie right after its stripped down.

As for today, I sand blasted and painted the clutch, brake, & throttle pedal assembly. I need to start somewhere and I have these parts just hanging around so, Pitter Patter I guess.

Here's a few pictures of the car the day Jass and I picked it up and then some pictures of the pedals.